Antibody Manufacturing

R&D Manufacturing

In custom antibody discovery, once lead selection is complete and it’s time to produce antibodies, a new set of dynamics quickly become key benchmarks: ”speed,” “scalability,” and “purity” are the mainstays that define success. In fact, this is when the quality of the process used in antibody production jumps to the top of the list.

Production from Hybridoma

Available exclusively to Antibody Solutions clients, MAbExpress™ is a highly personalized, responsive and agile technology that, when combined with our commitment to process excellence, enables us to deliver the high-quality, R&D grade, fit-for-purpose antibodies that you need for your drug research or in vivo animal studies. Through MAbExpress™, your team can cut production timelines by:

-

Generating a large quantity of the antibodies you need from a single lot, guaranteed by in-process monitoring

-

Leveraging bioreactors to scale up research-grade output

-

Securing production and purification for all antibody species (mouse, rat, human) and isotypes (IgG and IgM)

-

Capitalizing on the proven success of a standard MAbExpress™ program on multiple scales that delivers on specs like:

-

Fast turnaround to research-scale quantity of antibody

-

Manufacture-scale quantities of antibody

-

Quantities guaranteed by in-process monitoring

-

Low endotoxin

-

<0.1% Bovine IgG

-

Very low protease, host DNA and RNAse

-

High-purity antibodies for in vivo animal studies

-

Faster. More reliable. Animal-friendly. All the best attributes you look for in antibody production are natural outcomes of the combination of our science-based approach and MAbExpress™.

Recombinant Antibody Production

Starting from a sequence? Antibody Solutions can employ its experience in recombinant expression to deliver purified antibodies for all your R&D needs.

Beginning with de novo gene synthesis and expression vector design, Antibody Solutions can ensure the highest quality starting material, including:

-

Codon- optimized gene synthesis and cloning via Gibson assembly

-

Multiple Species (human, mouse, rat, rabbit) including chimeric constructs

-

Multiple isotypes (from IgG1 to IgG4)

-

Custom mutations (Fc, knob-in-hole heterodimers, etc)

-

Sequence verification and QC with low endotoxin plasmid preps

Equipped with the highest quality starting material, we can then proceed with recombinant antibody production and purification utilizing:

-

Mammalian expression hosts (CHO or HEK)

-

Optimized transfection system and harvest schedule

-

Suspension cell cultures for high yield (up to >1 g)

-

Option to generate stable cell line

-

Manufacturing grade resins for antibody purification

Taking on the tough challenges together

Our hallmarks in antibody purification and production are aligned to exactly what our clients need most: reliability, timeliness, and cost-effectiveness. To learn more about our antibody manufacturing process and see how it may be an ideal match for your team’s needs, just contact us to get the conversation started.

Related Resources

12 min read

Reading the Biotechnology Tea Leaves: Therapeutic Antibody Developments in 2023 and 2024

With its “Antibodies to Watch” publication, The Antibody Society provides a comp...

14 min read

Looking Into the Future: Therapeutic Antibody Trends

Although Antibody Solutions focuses primarily on therapeutic antibody discovery ...

1 min read

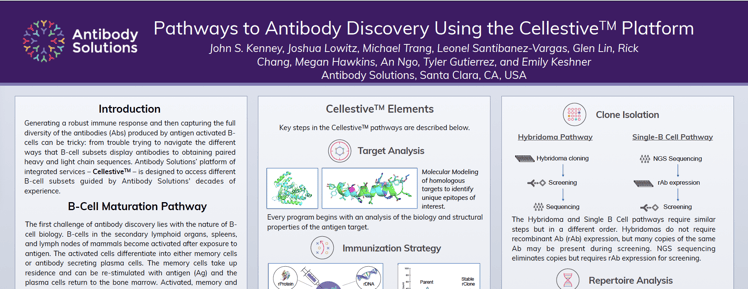

Pathways to Antibody Discovery Using the Cellestive™ Platform

Cellestive™ leverages the success of immune rodents in raising diverse and devel...